Drivetrain components operate at high operational loads. Many parts are exposed to critical functionalities. Laser surface hardening enhances the mechanical properties in local areas. It increases wear resistance, surface hardness and fatigue life while maintaining an unaffected core microstructure.

Benefits

- Local laser hardening of components exposed to wear for fully functional performance.

- Laser heat treatment of surfaces that are exposed to deformations during assembly and transport.

- Maximum flexibility for small batches of similar components with different requirements.

- Low distortion compared to other heat treatment processes.

Gears and shafts are other components perfectly suitable for laser hardening. Thanks to the flexibility offered by the laser heat treatment different areas in the same components can be treated to achieve different hardening requirements in case depth and hardness.

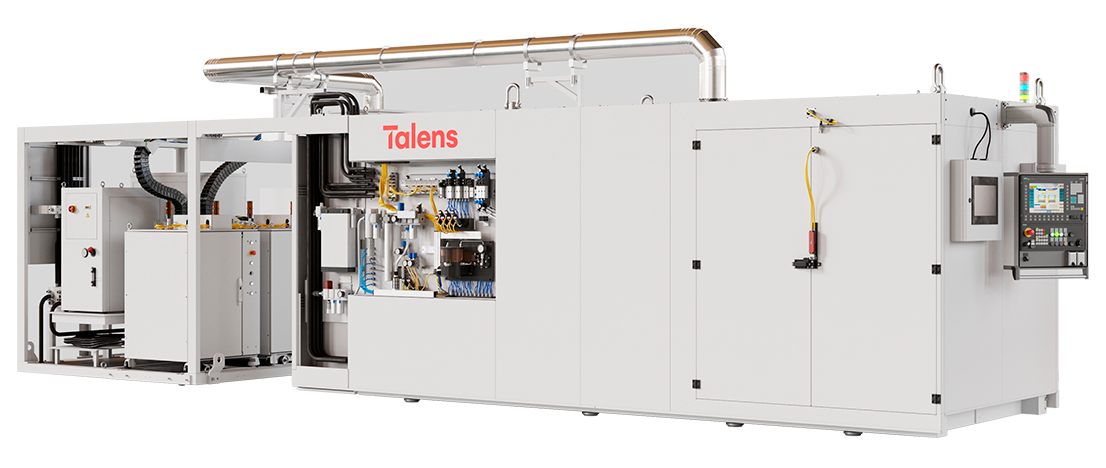

We can help you by applying our laser technology and experience

Contact us